Corporate

We produce stand-alone machines and complete lines to handle the entire packaging process for the pharmaceutical and cosmetic industries.

Today, the Marchesini Group caters for the whole packaging process from start to finish. It creates stand-alone machines and complete lines to package products such as blisters, bottles, carpules, jars, lipsticks, make-up, parfumes, syringes, tubes, vials through to putting the individual products into bundles, cases and on pallets.

The finished product is a combination of craftsmanship integrated with robotics and technology. This result has been achieved thanks to the expertise of the Group’s branches.

Every brand of the Group develops and manufactures specific machines for the whole packaging process in its plants located throughout Italy, while complete line assembly is coordinated from our Headquarters.

The Blister & Farcon plant in Carpi offers INTEGRA blister packaging machines, catering to various production needs with advanced technology for both low and high volumes.

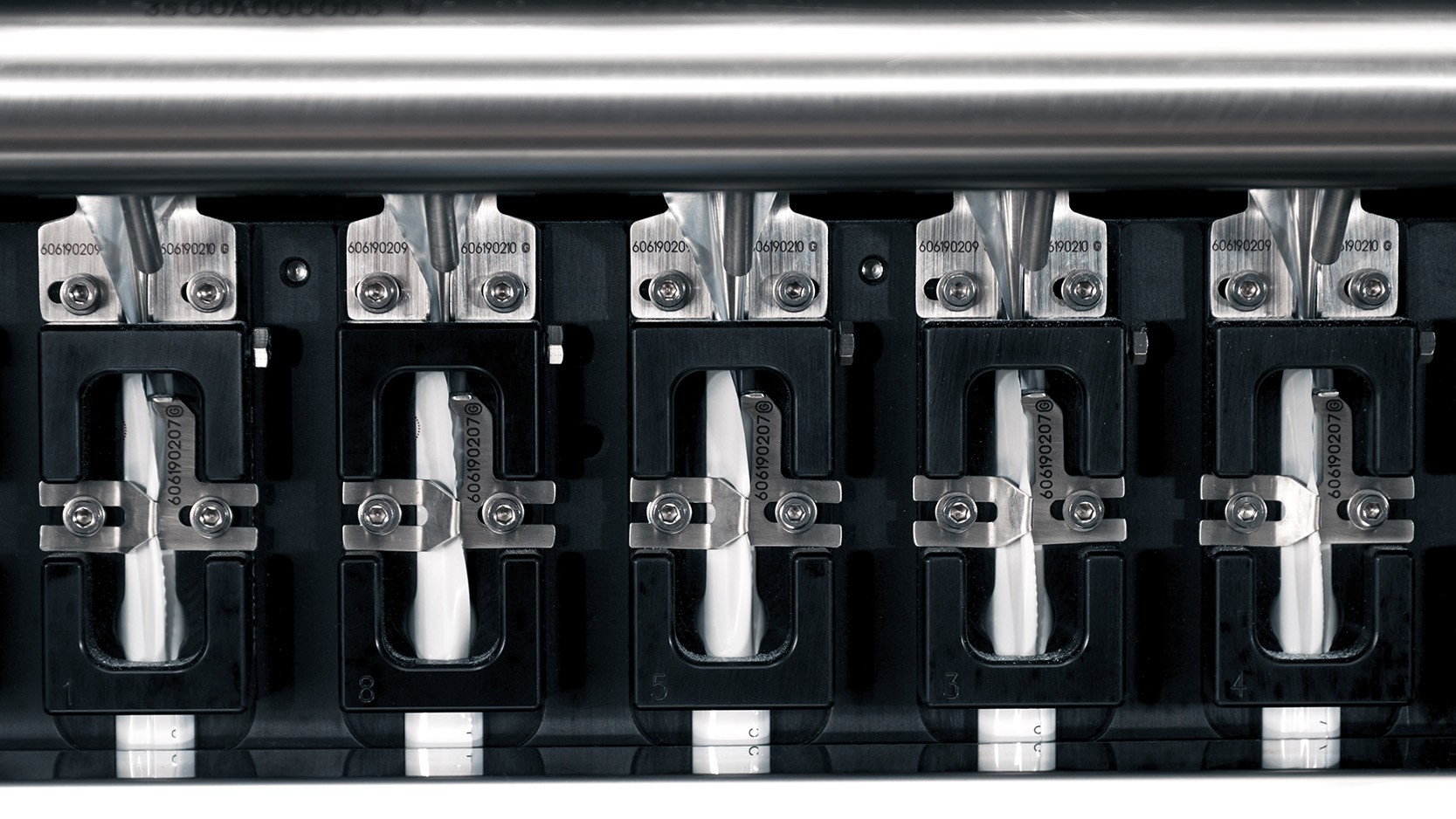

Counting machines process tablets and capsules, available in count-only and monobloc units with capping. They feature inspection systems for strict pharmaceutical standards.

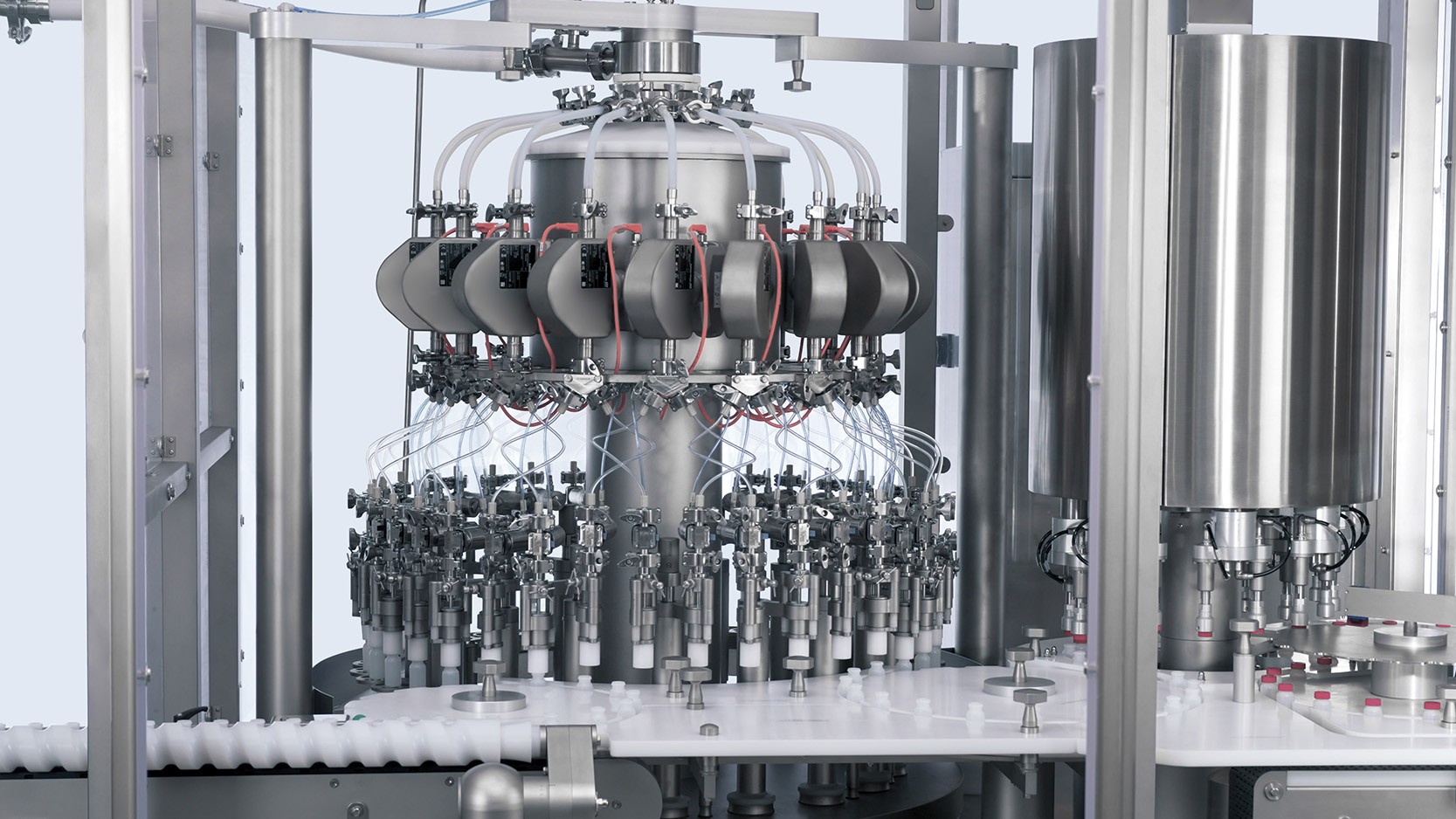

These machines fill and cap plastic or glass bottles, originally for pharmaceuticals but also used in cosmetics and nutraceuticals. They offer various filling technologies.

Stickpack machines from Schmucker produce tubular single-dose sachets, using up to 30% less material. They are versatile, easy to use, and suitable for various industries.

These machines form, fill, and seal sachets on all sides for various products. They offer rapid size changes and easy dosing adjustments, ideal for pharmaceuticals, cosmetics, and food.

These automatic machines package coated tablets and pills in strip packs sealed on all sides. They feature horizontal flow, in-line cartoner connection.

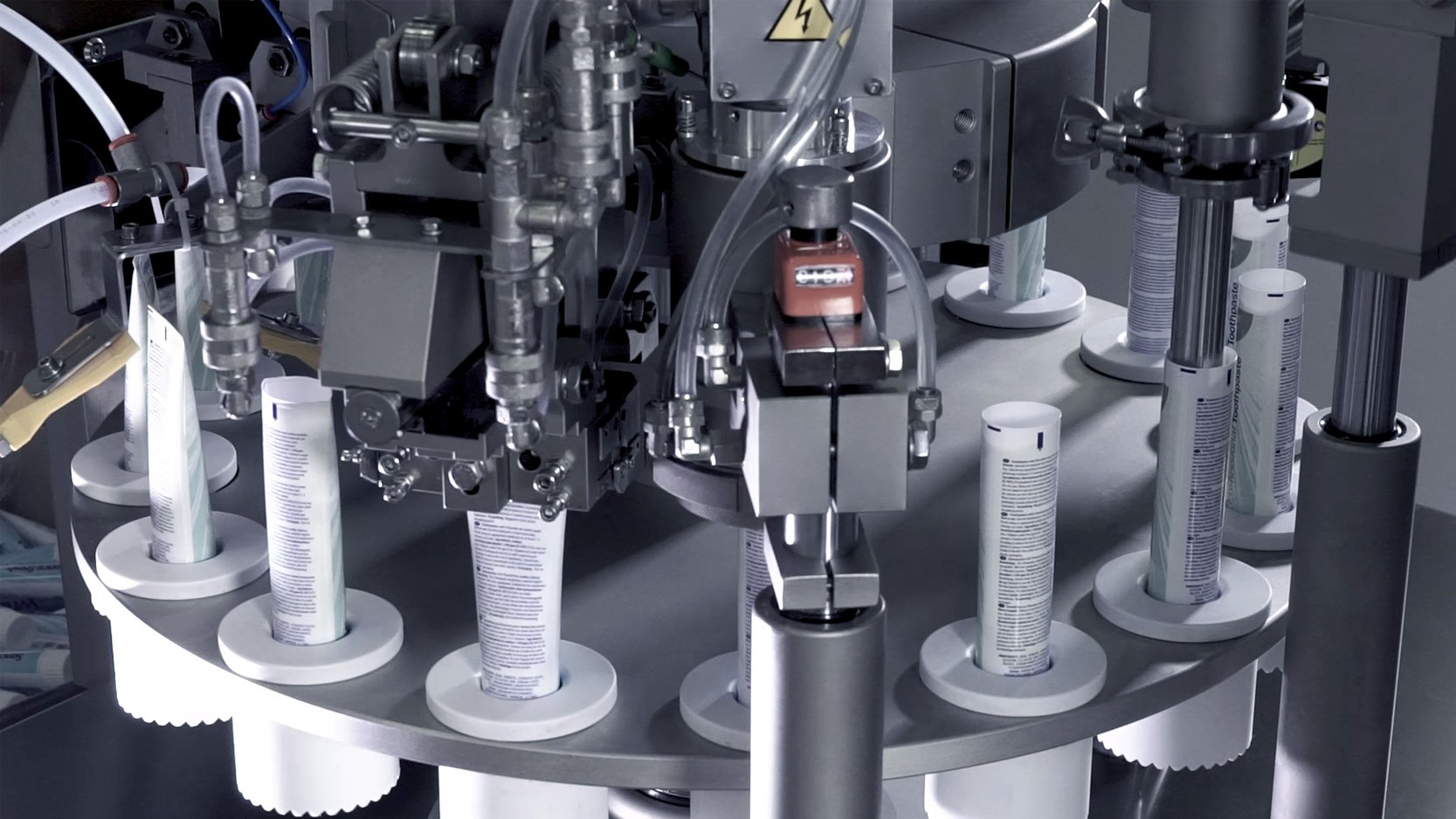

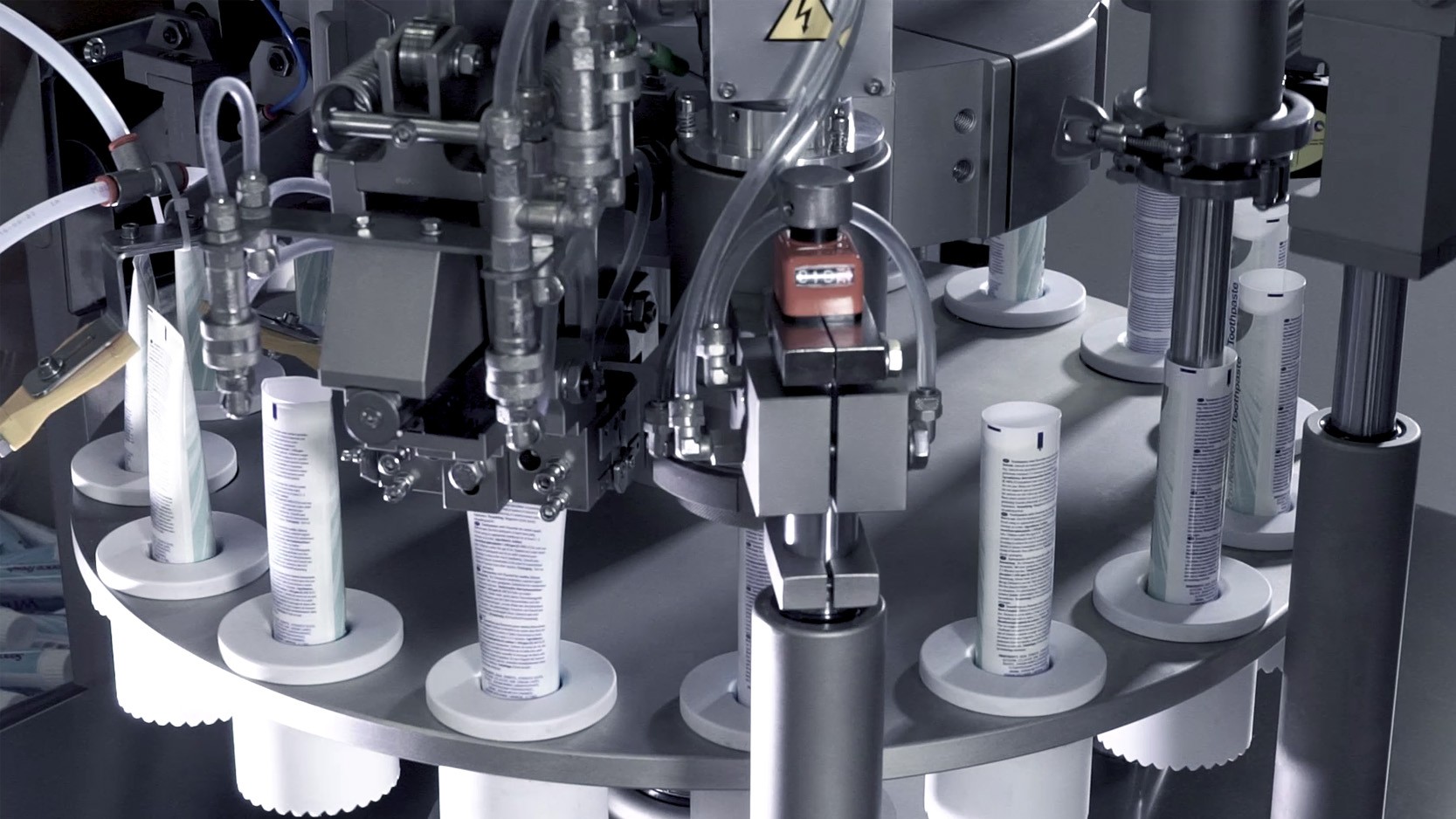

These compact machines fill and close squeezable tubes, ensuring uniform product distribution. They process metal, plastic, and laminate tubes with ease.

Marchesini Group’s machines use a 12-arm Pick & Place robot to package effervescent tablets in tubes, ensuring precise stacking and capping with on-board sensors for high-quality results.

Marchesini Group offers cutting-edge solutions for the beauty industry, specializing in advanced machinery for filling, capping, and packaging.

Our versatile and innovative machines ensure high-quality production for cosmetics, including lipsticks, mascaras, and lip balms, meeting the most specific customer requirements with precision and efficiency.

Compact tube machines ensure uniform distribution for metal, plastic, and laminate tubes. Available for beauty and pharmaceutical uses, including sterile products.

Machines for filling and capping plastic or glass jars. Rapid size changes, wide dosing range, and easy cleaning. Essential Marchesini Group features.

Lip balm filling machines meet cosmetic industry standards with advanced technology for precise, uniform filling, ideal for high-quality production

Flexible solutions for mascara and lip gloss with wiper or ball insertion units. Includes mechanical and robotized no-touch infeed systems.

Machines for filling and capping bottles in pharmaceuticals, cosmetics, and nutraceuticals, with various technologies and checks.

Compact lipstick filling machines ensure uniform distribution and meet custom mold requests for any shape, logo, or texture.