Corporate

For the nutraceutical branch of an American corporation we have constructed a line able to package an exclusive powder product: it is a vitamin supplement for breast milk, distributed to premature babies in hospitals. The project was assigned to Schmucker, the Marchesini Group company specialised in the construction of machines for packaging powders in stickpacks and sachets for the pharmaceutical, cosmetic, chemical and food industries.

When designing the production line, Schmucker was faced with a number of complex demands:

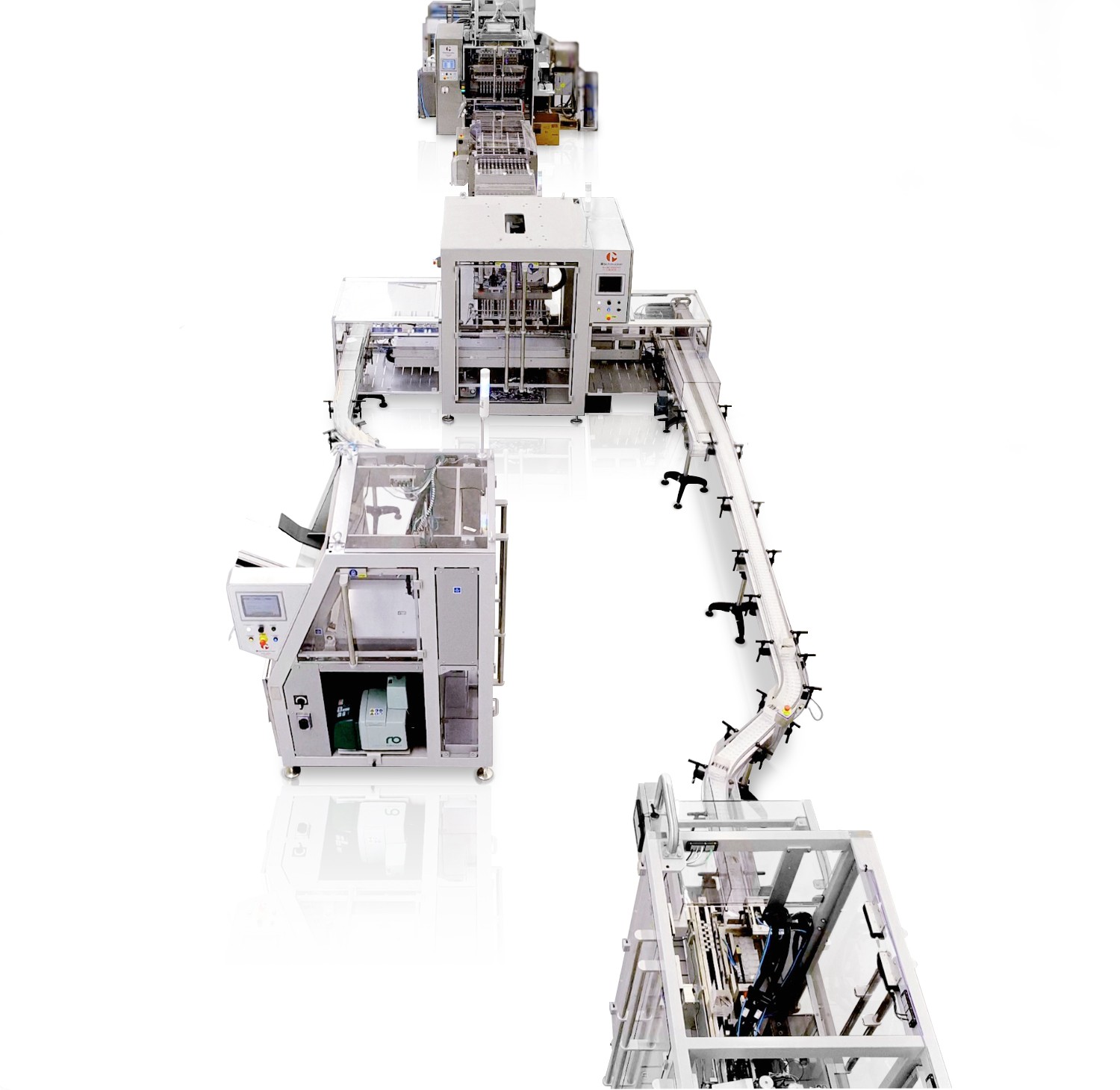

Upstream of the line is the Pharmastick MT1300 filling machine, a 12-lane vertical packaging machine for the production of stickpacks. Once the stick has been created, it is filled with the powder product by an auger dosing unit at a rate of about 600 sticks/min.

After this, the sticks are manipulated by a Pick and Place robot, which transfers them onto an elevator conveyor belt that directs all the sticks through a multi-lane weighing unit (supplied by a third-party producer). This unit weighs the individual sticks as they pass over the load cells, allowing any sticks not within the required weight tolerance to be rejected.

A new multi-arm picking robot manipulates the sticks and stacks them in the carton preformed by the VTF40, a vertical forming machine which forms cartons from a flat die-cut blank taken from a magazine.

The line is equipped with three control levels to ensure that the correct number of sticks are tidily stacked in the carton, after they have passed the weighing check process.

The filled, open carton now reaches the CV40, a closing machine which closes the carton and applies the data matrices and other serialisation data on the pack, as well as checking closing and the addition of the data.

The CV40 carton closing machine is able to apply various types of top closures such as tuck-in, glue or adhesive sticker, and is extremely versatile, with the ability to package different types of products.

The closed carton then enters an X-ray machine which checks that it does not contain any items such as metals or foreign bodies.

The project for a line able to package a special vitamin supplement for breast milk, distributed to premature babies in hospitals, was assigned to Schmucker, one of Marchesini Group's brand.

Discover it by watching the video.

The project for a line able to package a special vitamin supplement for breast milk, distributed to premature babies in hospitals, was assigned to Schmucker, one of Marchesini Group's brand.

Discover it by watching the video.

Schmucker was the first Italian business to widely distribute the stickpack technology throughout Europe. Stickpacks were initially used almost exclusively in the food industry, but they later became very popular with pharmaceutical companies too.

The stickpack is indeed an intelligent solution for many reasons: speaking of the producer, it guarantees savings in terms of logistics, energy and amount of material used and speaking of the end user, since it is a “smart” format, it is much easier and safer to use.

Schmucker was the first Italian business to widely distribute the stickpack technology throughout Europe. Stickpacks were initially used almost exclusively in the food industry, but they later became very popular with pharmaceutical companies too.

The stickpack is indeed an intelligent solution for many reasons: speaking of the producer, it guarantees savings in terms of logistics, energy and amount of material used and speaking of the end user, since it is a “smart” format, it is much easier and safer to use.